Thermal System Modeling for Efficient Buildings

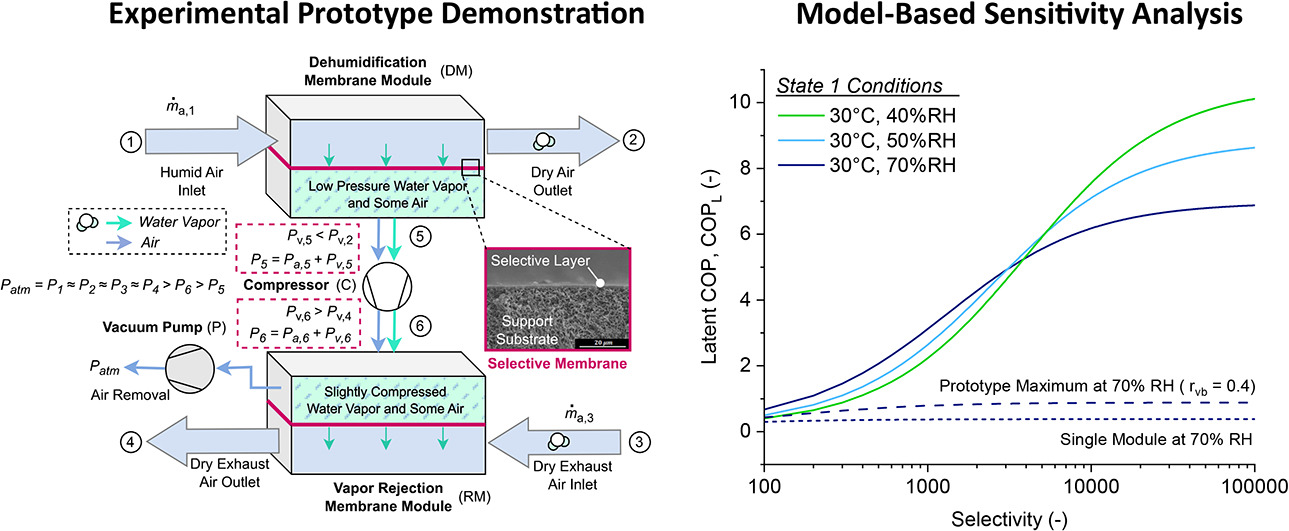

Developing models, accompanied by experimental prototypes, based on the first and second laws of thermodynamics to assess the energy performance of a range of thermal technologies, including membrane dehumidification, liquid desiccants, evaporative cooling, and other environmentally friendly technologies. We also develop discretized physical models for heat and mass transfer processes, validated with experimental data.

Current Projects (updated 1/13/2026): Currently, we are developing thermodynamic models for closed-cycle membrane dehumidification systems, vacuum-assisted desiccant regeneration technologies, and energy recovery in dehumidification systems.

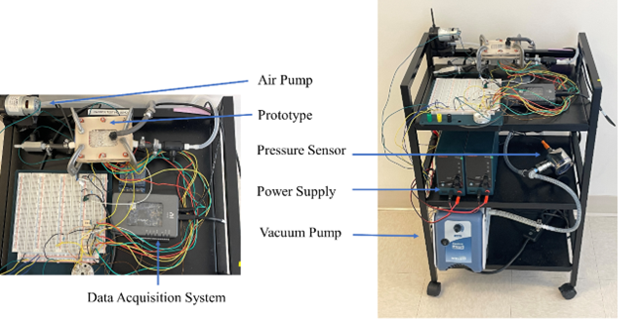

Prototype Development of Early-TRL Thermal Systems

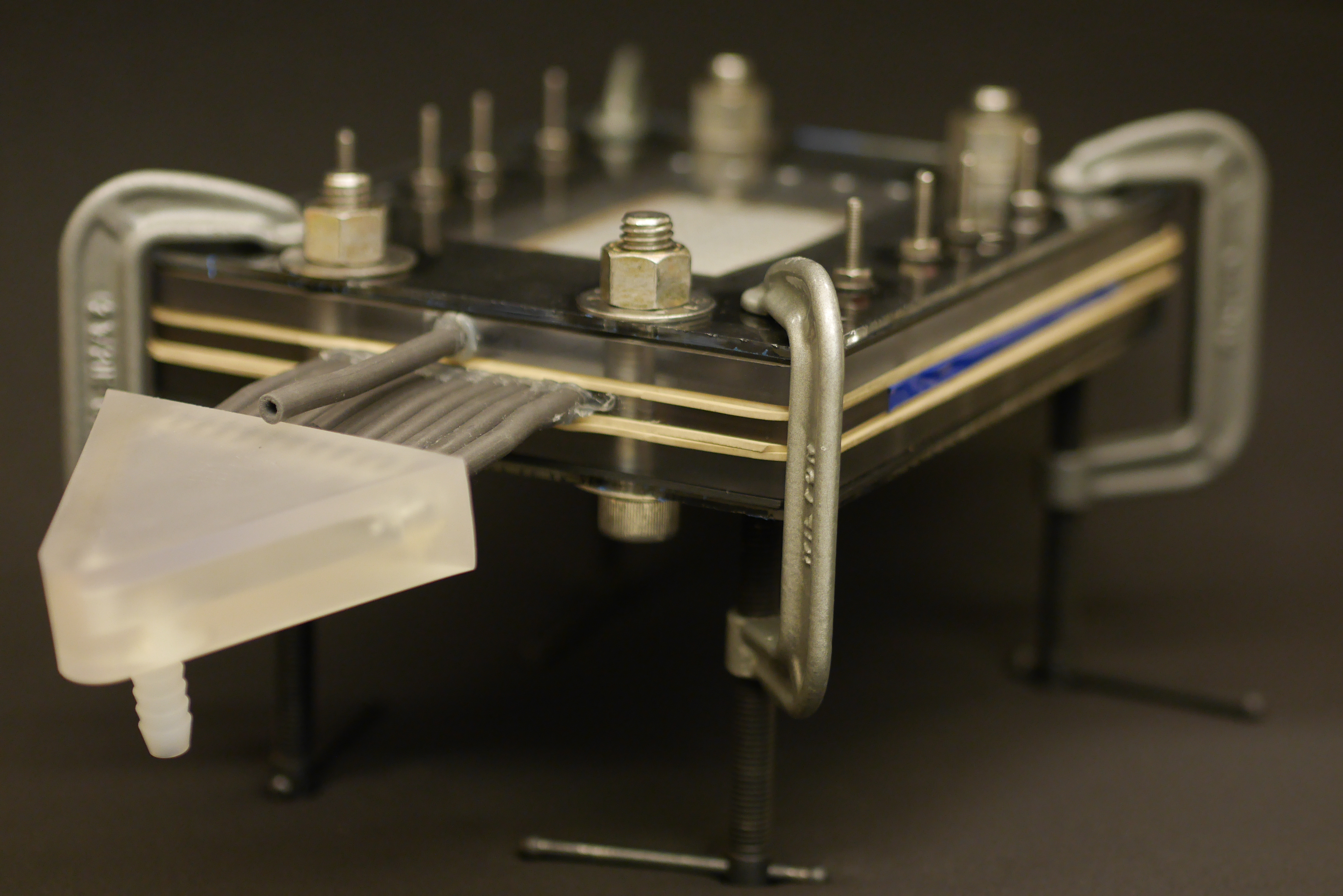

We develop experimental prototypes, and the accompanying testing facilities/infrastructure for next-generation cooling/heating, dehumidification, and energy storage technologies.

Current Projects (updated 1/13/2026): Currently, we are designing experimental facilities for both membrane dehumidification and desiccant regeneration experiments, followed by prototype development and demonstration. We are also evaluating DC-powered atmopsheric water harvesting prototypes in partnership with H2O Now.

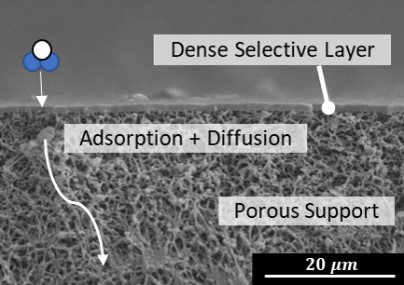

Selective Membrane Fabrication and Characterization

In order to support our analysis of novel, membrane-based air conditioning systems, membranes must be made in lab, as they are not commercially available. Our efforts in this field have focused on the application of high-performance polymer coatings onto new support substrates. Furthermore, of notable interest was our analysis of the temperature dependence of many polymeric vapor separation membranes, adding to the benefits of non-isothermal vacuum membrane dehumidification.

Current Projects (updated 1/13/2026): We are extending our work on Pebax-based membranes and also working with scientists at Kraton in Houston, TX on new membrane materials. We are also collaborating with Prof. Manish Kumar on the development and implementation of carbon molecular seive membranes for dehumidification applications.

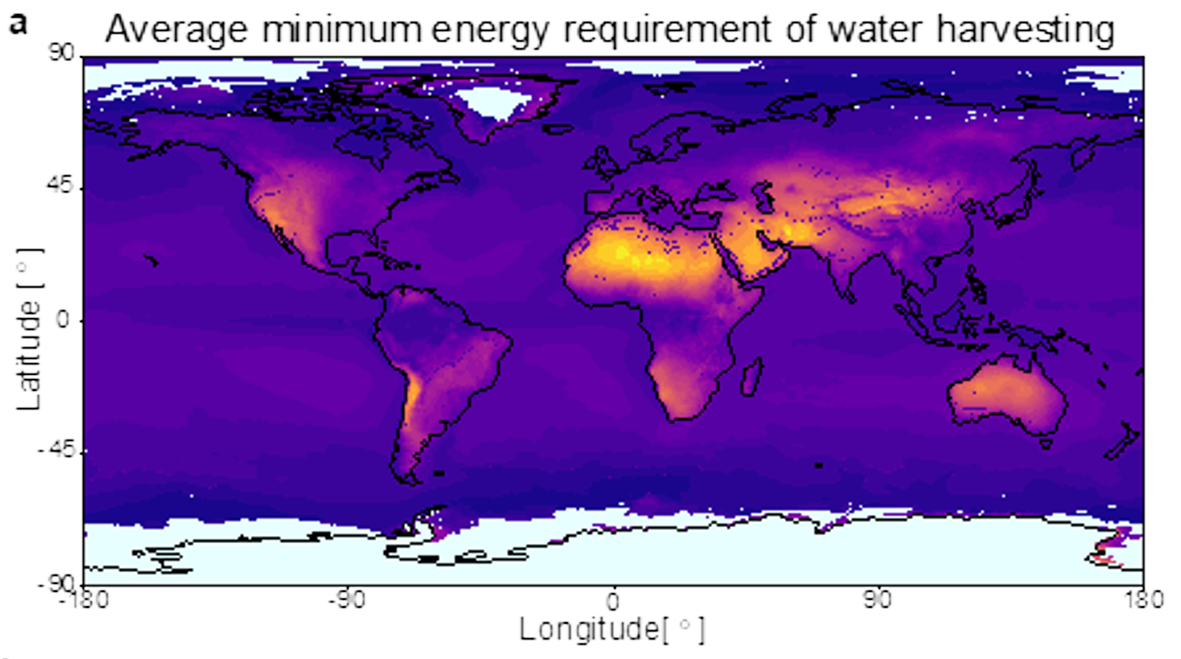

Atmospheric Water Harvesting

As water scarcity grows, we will need to rely on a range of different technologies for producing drinking water. Atmospheric water harvesting has the advantage of providing a de-centralized source of clean water. Our research in this area focuses on the thermodynamic system design and modeling/simulation of various technologies including, water vapor selective membrane separations, metal organic framework (MOF) sorbent systems, and dew systems. Additionally, we have developed a theoretical “least work” framework to provide the first robust comparison method across different technology categories. We are employing super computing resources to calculate global spatial-temporal trends in AWH energy requirements.

Current Projects (updated 1/13/2026): We are collaborating with H2O Now on lab and field testing of DC-powered, refrigeration-based atmospheric water harvesting systems for agricultural applications. We are also collaborating with Prof. Misztal’s group on evaluating water quality in atmospheric water. Furthermore, we are working on quanitifying the potential environmental impacts of widespread AWH.

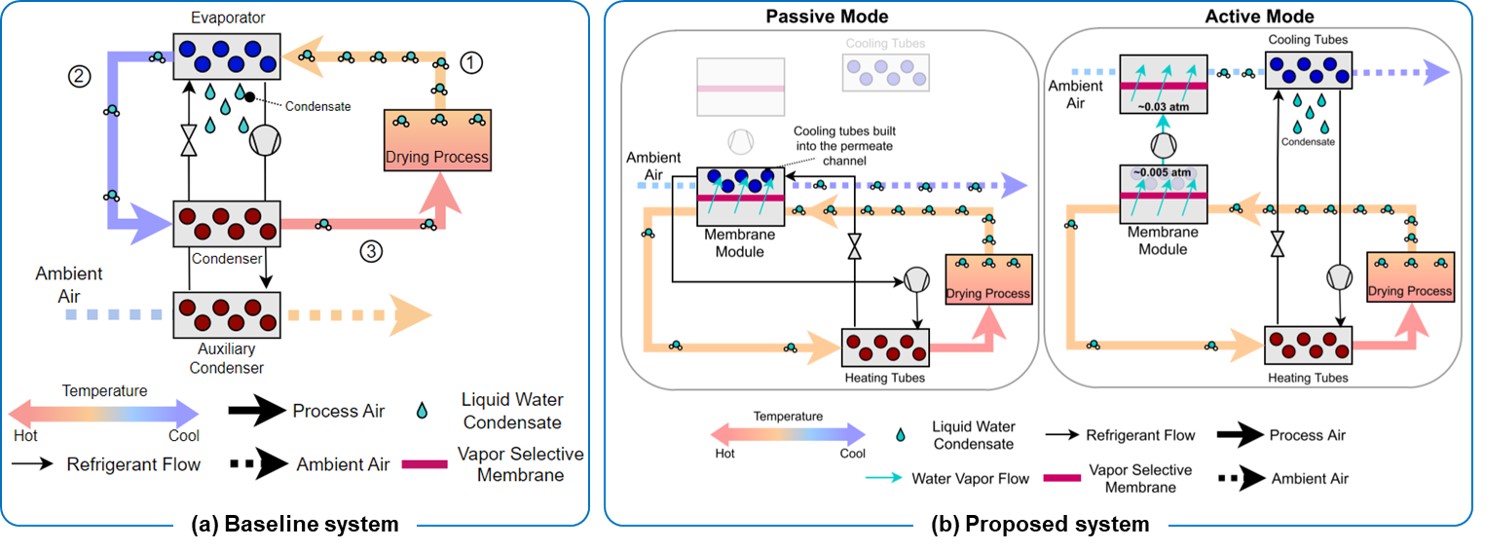

Membrane-Assisted Industrial Heat Pump Dryers and Low-GWP Wood Dryers

Industrial drying is largely carried out using high-temperature combustion gases. Heat pumps are a promising electric option to replace existing systems, but cannot reach as high of temperatures and are limited by dehumidification loads. We proposed a system concept that combines membrane dehumidification and heat pumps for more efficient, electricity-driven industrial drying and received $2.4 million in funding from the Advanced Manufacturing Office.

In addition to the membrane-assisted drying cycle, we were also involved with a project focused on wood drying with heat pump systems utilizing low-GWP refrigerants. Our work in this space involves quasi-dynamic cycle modeling, heat exchanger design, and test facility planning.

Current Projects (updated 1/13/2026): Currently, we are not working in the space on industrial drying, though it continues to be an area of high relevance to our group’s interest in water vapor separations and thermal processes. Much of this work has been published and can be found on Dr. Fix’s Google Scholar page.

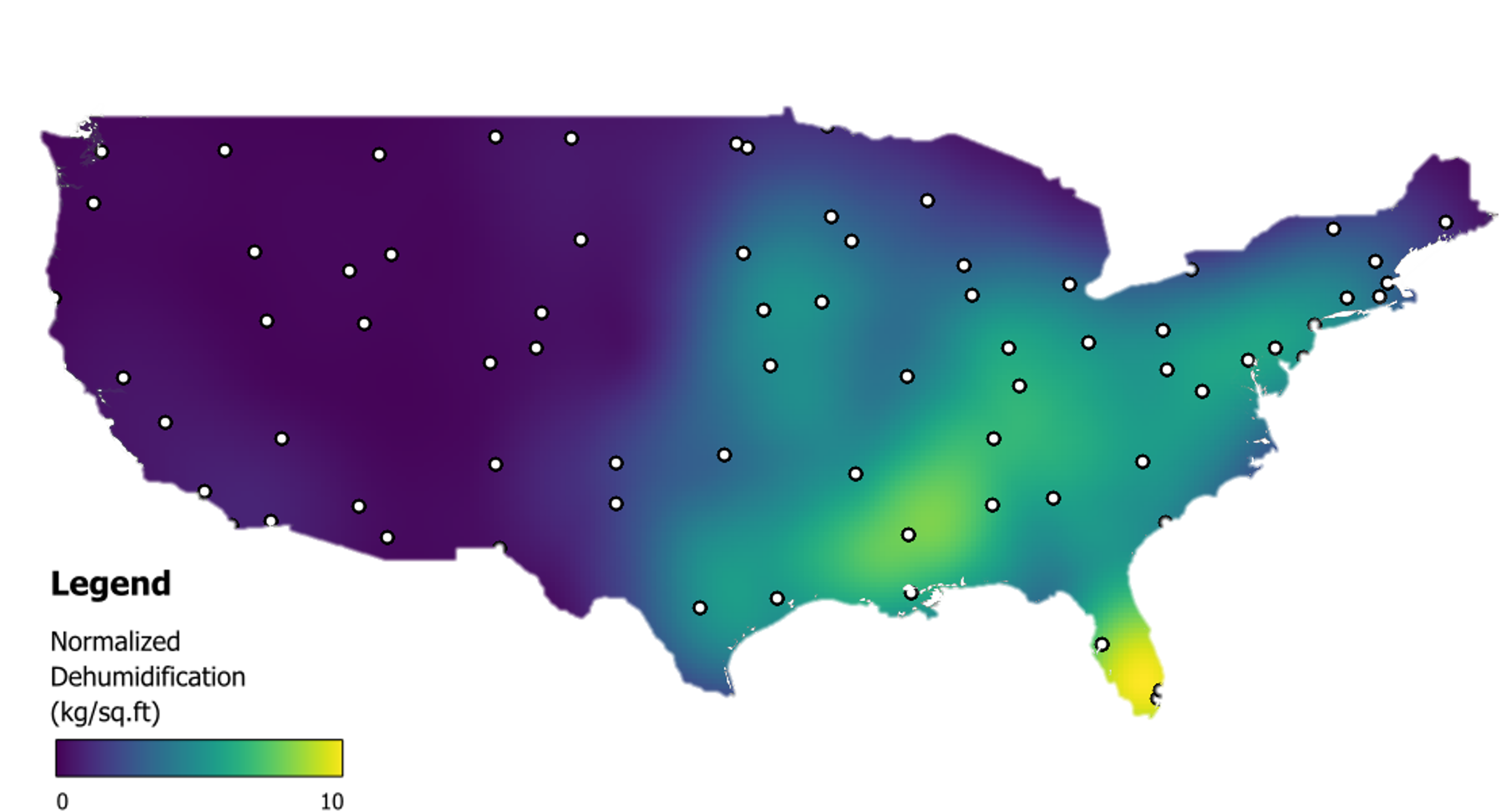

Air Conditioner Condensate for Water Reuse

We are broadly interested in the collection and re-used of atmospheric water condensed on cooling coils in HVAC systems. In addition to our own technical analyses in this space, we have also conducted field tests with the Environmental Protection Agency (EPA). We are interested in exploring the energy, economics, environmental, and health aspects of air conditioner condense recovery and re-use.

Current Projects (updated 1/13/2026): Currently, we are finalizing our publication with the EPA and beginning new projects focused on combined analysis of air quality and water quality. Furthermore, we are exploring the magnitude of water production by building air conditioners using building energy modeling software.

Low-GWP Cold Climate Heat Pumps

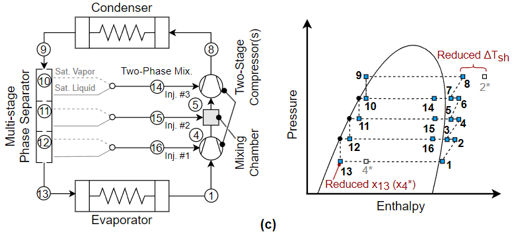

At the Center for Environmental Energy Engineering at UMD, we developed models for a cold-climate heat pump that incorporates two-phase refrigerant injection. We also helped set the foundation for experimental development and testing. In the future, the Fix Lab will collaborate on low-GWP cooling and heating technologies, bringing our particular expertise in sorbents and efficient system design.

Current Projects (updated 1/13/2026): Currently, we are not working in the space on industrial drying, though it continues to be an area of high relevance to our group’s interest in water vapor separations and thermal processes. Much of this work has been published and can be found on Dr. Fix’s Google Scholar page.

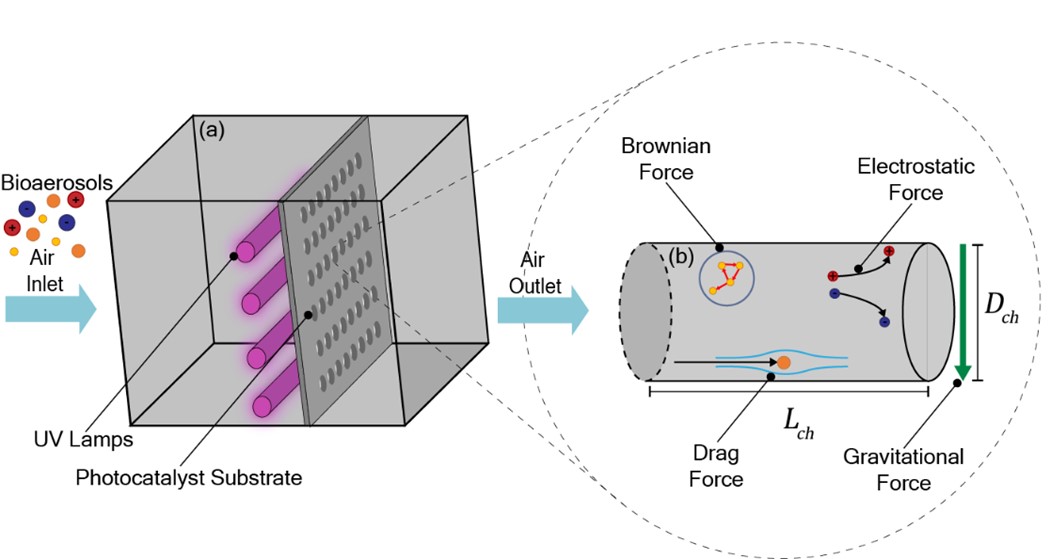

Particle Deposition in HVAC Equipment

As part of this research effort, we modeled the dust (particle) deposition expected in membrane-based HVAC equipment and identified key factors leading to increased dust deposition. Significant future work is required in this space as membrane systems become more common in the HVAC industry. Very little literature exists on assessing the impact of dust and fouling in vapor selective membranes, though it is a highly-researched topic for water desalination membranes. Our team, led by another graduate student, also modeled particle deposition on photocatalytic air purification system surfaces to evaluate bioaerosol inactivation efficiency. Particle deposition is critically important for photocatalytic reactions to occur in air purifying devices.

Current Projects (updated 1/13/2026): Currently, we are not working in the space on industrial drying, though it continues to be an area of high relevance to our group’s interest in water vapor separations and thermal processes. Much of this work has been published and can be found on Dr. Fix’s Google Scholar page.